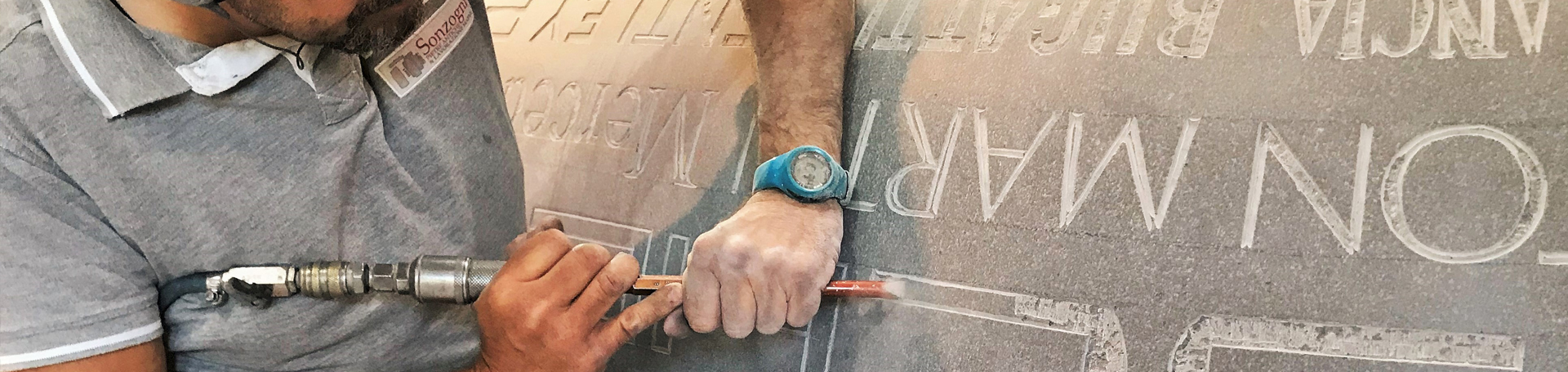

From design to installation, we process marble and stone from the concept phase of the project through to its maintenance and therefore its restoration over time.

Marbles and stones live in symbiosis with the environments in which they are installed: this is why it is necessary to be an expert of such raw material, but also the intentions and demands of the customer.

Starting from the selection of high quality marbles, we recommend the best cutting solutions and finishes, illustrating the ideal processing options for each individual project.